Objectives:

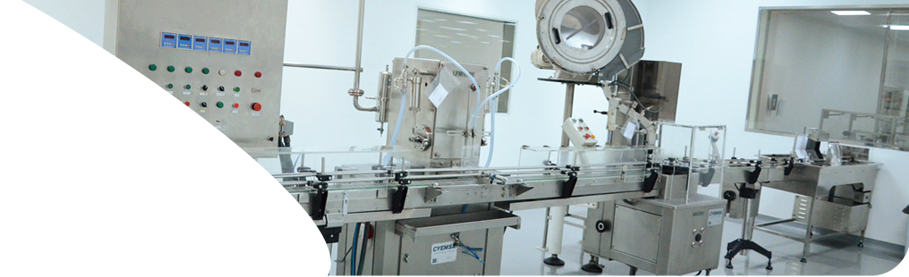

Production management, also called operations management, planning and control of industrial processes to ensure that they move smoothly at the required level. In manufacturing operations, production management includes responsibility for product and process design, planning and control issues involving capacity and quality, organization and supervision of the workforce. GOOD MANUFACTURING PRACTICES AND REQUIREMENTS OF PREMISES, PLANT AND EQUIPMENT FOR PHARMACEUTICAL PRODUCTS WHO defines Good Manufacturing Practices (GMP) which covers all aspects of the manufacturing process.

Production/operations management is the process, which combines and transforms various resources used in the production/operations subsystem of the organization into value added product/services in a controlled manner as per the policies of the organization. Therefore, it is that part of an organization, which is concerned with the transformation of a range of inputs into the required (products/services) having the requisite quality level.

The set of interrelated management activities, which are involved in manufacturing certain products, is called as production management. If the same concept is extended to services management, then the corresponding set of management activities is called as operations management.

Functions:

Production is defined as “the step-by-step conversion of one form of material into another form through chemical or mechanical process to create or enhance the utility of the product to the user.” Thus production is a value addition process. At each stage of processing, there will be value addition.

Following are the activities which are listed under production and operations management functions:

1. Location of facilities

2. Plant layouts and material handling

3. Product design

4. Process design

5. Production and planning control

6. Quality control

7. Materials management

8. Maintenance management.